Product Center

Silicon dioxide

Time:2024-07-21View:577

Precipitated silica

Dry production site

package

Application Cases

PRODUCT PRESENTATION

Silica is a general term for white powdery X-ray amorphous silica and silicate products, primarily referring to precipitated silica, fumed silica, and ultrafine silica gel. It also includes powdery synthetic aluminum silicate and calcium silicate. White carbon black is a porous substance, and its composition can be represented as SiO2·nH2O, where nH2O exists in the form of surface hydroxyl groups. It is soluble in caustic alkali and hydrofluoric acid, but insoluble in water, solvents, and acids (except hydrofluoric acid). It is high-temperature resistant, non-combustible, tasteless, odorless, and possesses excellent electrical insulation properties.

Chinese Name:白炭黑

English Name: Silica

CAS Number: 10279-57-9

EINECS Number:238-878-4

Appearance: White powder, granules, or irregular lumps.

True Density:Approximately 2.0 g/mL

Bulk Density:Approximately 0.2 g/mL

Properties: High temperature resistance, non-combustible, excellent electrical insulation.

Chemical Properties

- Reacts with caustic soda:

SiO2·nH2O+2NaOH=Na2SiO3+(n+1)H2O

- Reacts with hydrofluoric acid:

SiO2·nH2O+4HF=SiF4+(n+2)H2O

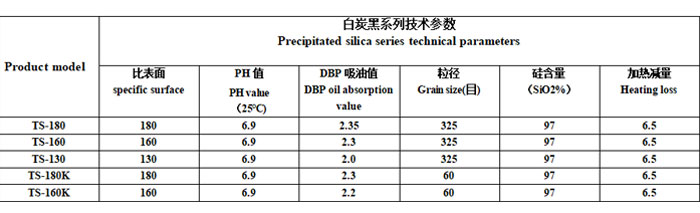

KEY CHEMICAL INDICATORS

- SiO2 content (dry): ≥90%

- Residue (45μm): ≤0.5%

- Loss on drying: 4.0-8.0%

- Loss on ignition (dry): ≤7.0%

- pH value: 5.0-8.0

- Total copper content: ≤30 mg/kg

- Total manganese content: ≤50 mg/kg

- Total iron content: ≤1000 mg/kg

- DBP absorption value: 2.00-3.50 cm³/g

- Specific surface area: varies with different uses, generally 145-165 m²/g (HT2), 165-185 m²/g (HT1), 200-300 m²/g (HT3)

KEY PHYSICAL PROPERTIES (Cooperate with rubber products)

- Tensile strength: ≥17.0 MPa

- Elongation at break: ≥675%

- Modulus at 100% elongation: ≥6.3 MPa

PRPARATION METHOD

White carbon black is broadly classified into precipitated silica and fumed silica based on production methods.

Fumed silica: Typically, fumed silica appears as white amorphous, flocculent, semi-transparent solid gel-like nanoparticles (particle size less than 100 nm), is non-toxic, and has a large specific surface area. Fumed silica is entirely nano-silica, with product purity reaching 99% and particle size as small as 10-20 nm. However, its preparation process is complex and costly.

Precipitated silica: Divided into traditional precipitated silica and special precipitated silica. The former is produced using sulfuric acid, hydrochloric acid, CO2, and water glass as basic raw materials. The latter is produced using special methods such as supergravity technology, sol-gel method, chemical crystal method, secondary crystallization method, or reverse micelle microemulsion method.

1.Fumed silica: Mainly used as a reinforcing agent for silicone rubber, as a thickener for coatings and unsaturated resins, with ultrafine silica gel and aerogel primarily used as matting agents for coatings, thickeners, and anti-blocking agents for plastic films.

2. Precipitated silica: Also known as the sodium silicate acidification method, involves reacting water glass solution with acid, followed by precipitation, filtration, washing, drying, and calcination to obtain silica. Most domestic production enterprises use the precipitation method. Precipitated silica is mainly used as a reinforcing agent for natural rubber and synthetic rubber, a toothpaste abrasive, a filler and reinforcing agent in rubber, a carrier for fire extinguishing agents, feed carriers, cosmetic carriers, matting agents, pigments, paints, coatings, bactericides, pesticide carriers, and many other industries.

- Prev:sodium silicate

- Next:Silica sol