Product Center

Silica sol

Time:2024-07-21View:624

SILICA SOL

Ion exchange production scenario

package

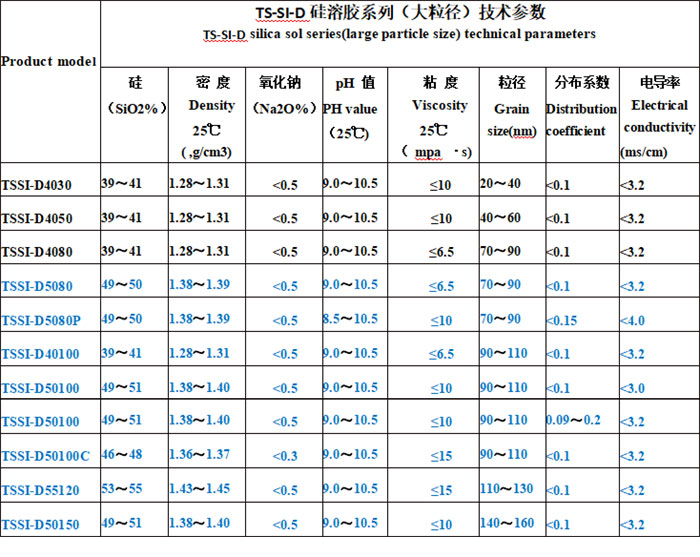

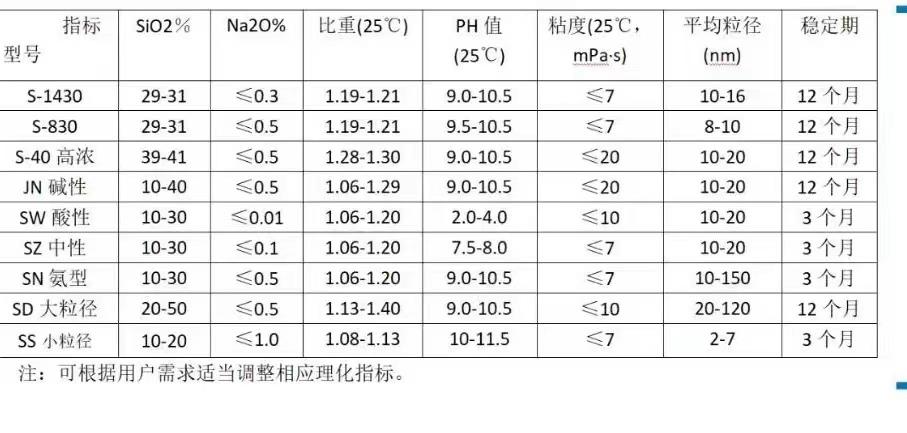

TECHNICAL INDEX

Application Cases

Product Name:Silica Sol

Product Model: TS-40100

Batch Number: PP240124242

SiO2 Content: 40%

Average Particle Size: 101.3 nm

Viscosity: 2.73

Specific Gravity: 1.299

pH: 9.6

Sodium Content: 0.07

Caution:This product is a general non-hazardous chemical. It should not be exposed to direct sunlight and should be stored in a cool place with a temperature between 2-40°C.

硅溶胶(English name: Silica solution) is a colloidal solution, odorless and nontoxic. Silica sol is a dispersion of nano-sized silica particles in water or solvent. Since SiO₂ in silica solution contains a lot of water and hydroxyl, silica solution can also be expressed as SiO₂.nH₂O.

There are different ways to prepare silica sol. The most commonly used methods are ion exchange, one-step hydrolysis of silicon powder, silane hydrolysis and so on.

BASIC INFORMATION

The ion exchange process of silica sol was developed by NALCO Company of the United States in the 1940s, and then perfected by DuPont Company of the United States in the 1950s and 1960s. It is the most mature and widely used process. This process has certain requirements for water glass, ion exchange resin and other materials and operation technology, which are the weakness of Chinese products. Relatively speaking, the one-step hydrolysis of silicon powder is relatively simple and widely used in China. However, the silica solution prepared by this method is usually about 10-20 nanometers in particle size, and the interface between particles is unclear, and the morphology is aspheric and uncontrollable, and the interface between particles is unclear, so it is usually only used in foundry and other industries, but it has not made great achievements in many fields with higher requirements such as precision polishing and accelerant. Compared with internationally renowned silica sol brands, the main disadvantages of domestic silica solution are high impurity content, no strict control of particle size, no strict detection of particle specific surface,low concentration of silica, poor stability under acidic or neutral conditions, short service life, more or less color, few varieties and so on. Internationally renowned silicone gel brands include DuPont and Grace's LUDOX series.

DEVELOPMENT

Silica sol inorganic polymer coatings have been developed in recent years. The key technology of preparing the coating is to remove water-soluble sodium ions from water glass by special methods. Generally,it can be realized by ion exchange, acid neutralization, water decomposition, electrodialysis, etc.,so as to generate a colloidal aqueous solution of ultrafine silica particles with a particle size of 580nm (generally2

emulsion particles are 800- 1000nm), in which the content of Si20 is 20%-30% and Na20 is 0.3%, and the proportion of silicon oxide and sodium oxide is above 40%. Silica sol inorganic polymer coating was prepared with this silica solution/glue as base material pigment and various additives.When the silicon solution loses moisture, the monomer silicic acid gradually polymerizes into highly polymerized silica gel. With the evaporation of moisture, the colloidal molecules increase and finally - SIO-O-SIO- coating: IO-SI-OH+HO-SI-OH Because of the low content of NA20 in silica sol, silica solution has a certain amount of film-forming dissolution characteristics,and its water resistance and heat resistance are obviously better than those of organic coatings. The coating film is dense and hard, does not generate static electricity, and all kinds of dust in the air are difficult to adhere. In architectural coatings, its anti-pollution ability is strong.

Fine particles have strong permeability to the base course, can penetrate into the base course through capillaries, and can react with calcium hydroxide in the concrete base course to generate calcium silicate, which makes the coating have strong adhesion.

However, the volume shrinkage of silica sol is large during the film forming process, and the film is easy to crack. Silica solution can be dissolved in acrylate ,vinyl acetate and other emulsions at will. Their characteristics complement each other, and excellent organic and inorganic composite coatings can be prepared.

CHARACTER

Silica sol is a colloidal solution, odorless and non-toxic, and its molecular formula can be expressed asmSi02nH20.

1. Because the colloidal particles are fine (10-20nm) and have a considerable specific surface area, the particles themselves are colorless and transparent, which does not affect the true colors of the covered objects.

2. The viscosity is low, and water can permeate everywhere, so the dispersibility and permeability are very good when mixed with other substances.

3. When the water in silica sol evaporates, colloidal particles are firmly attached to the surface of the object, and silicon-oxygen bonding is formed between particles, which is a good adhesive.

USE

1. Used as a binder for various refractory materials,it has the characteristics of strong adhesion and high temperature resistance (1500°C-1600°C).

2. Used in coating industry, it can make the coating firm, and has the functions of anti-pollution, anti-dust, anti-aging and fire prevention.

3. Used in precision casting of thin shells, it can make the shell shape strong and the casting finish high. Its molding quality is better than that of sodium silicate, and substituting ethyl silicate for molding can reduce the cost and improve the operating conditions.

4. Silica sol has a high specific surface area and can be used for catalyst preparation and catalyst carrier.

5.Used in papermaking industry, it can be used as cellophane anti-sticking agent,paper pretreatment agent for photography, anti-skid agent for cement bags, etc.

6. Used as sizing agent in textile industry, it can be used together with oil agent to treat the spinnability of sheep hair and rabbit hair, reduce broken ends, prevent flying flowers, improve finished products and increase economic benefits.

7. Used as silicon steel sheet treatment agent, kinescope dispersant, floor wax anti-sliding and so on.

PROCESS FOR PREPARING SILICA SOLUTION

Method for treating dilute solution of sodium silicate with ion exchange resin; Neutralizing dilute solution of water glass with sulfuric acid; Hydrolyzing silicate, etc. Its basic principle is to remove sodium ions that are easily soluble in water. Examples are as follows:

Ion exchange method

a. Ion exchange resin.

The cation exchange resin adopts strong acidic styrene cation exchange resin; Anion exchange tree refers to weak basic styrene anion exchange resin.

b.Production process

The sodium silicate solution with a modulus of 3.5 is diluted with water to contain SiO24% , Na201.15%; Passing the liquid through a flash column filled with cation exchange resin, The product contains SiO23.6%, NA200.005% and the molar ratio of SiO2/Na2 is 0. 703, Silicic acid gel dilute solution with PH value of 2.5.

Ion exchange is an equilibrium reaction, and the reaction process is that Na+ replaces H+ on the cation exchange resin when the silicic acid solution containing Na+ passes through the exchange tree.

So Na+ in the water glass has been removed,and H+ cation, silicon ion and SiO3 in sodium silicate generate active silica sol dilute solution and flow out.

The ion exchange quality of silica sol is related to the following factors:

Degree of resin regeneration, equilibrium property,height of resin, inflow depth, ion size,etc.

The silica sol passed through the cation exchange column is diluted and then passed through the weakly basic anion resin exchange column to remove the anion CL- in the liquid, so as to achieve a more stable state. The concentration of dilute silica gel flowing out of the exchange column is very low, so it needs to be concentrated. In order to prevent gelation during concentration, a stabilizer must be added quickly before concentration. The stabilizer is usually MOH (M is L,Na,K,Rb,Cs,NH4.NH2, etc.) The dosage of stabilizer should be Appropriate, if it is less than 1% of the mole number of Sio2, it is difficult to play a stabilizing role; If it exceeds 5%, the purity of the product will be reduced. Take 5kg of the above silica sol and adjust the PH value to 78 with 10%NAOH solution. Take 900g of adjustment liquid and inject it into the pressure reducer for true decompression and concentration. On the principle of keeping the liquid level in the container constant, slowly added the remaining 4100g of adjustment liquid. The concentration temperature was kept at 78°C, and finally 900g containing SiO 220% was obtained. Na 200.33% silica sol with pH 9.6 has an average particle size of about 16mum。

After ion exchange, ion exchange resin has lost its exchange energy. Wash with dilute hydrochloric acid, and replace Na+ on the resin with H9+ in HCL. And the active groups of the ion exchange resin are oxidized, so that the resin is regenerated and the exchange capacity is restored. After regeneration, the ion exchange tree finger must be washed with distilled water to the specified PH value for next use.

TECHNICAL PROPERTIES OF SILICA SOL

Si02 content is 20%-30% (content >26%% based on H2Si03).

Moisture 70%-80%

Specific gravity 1.14-1.21

Na20 content 0.4%-0.5%

Viscosity (Tu 4)10.9S can be stored for one year. The concentration stage of silica sol production is a process link with high energy consumption and long cycle. The traditional concentration method generally adopts the method of reducing atmospheric pressure to dehydrate, so that silica sol with the required concentration can be obtained.

Silica sols can be divided into alkaline silica sols and acidic silica sols according to their different pH values. They are all important fine chemical products, which have different important uses: for example, alkaline silica sol is used in precision casting,

exterior wall coatings anid other fields; Acidic silica sol is used in color picture tubes, colloidal lead-acid batteries, and electrostatic flocking technology imported from

abroad.

- Prev:Silicon dioxide

- Next:Inorganic silicon resin